Infrared thermography: for better insulation and to be eco-responsible.

-

Categories :

Promote

+32 (0)2 460 18 60

Good maintenance of your installations does not always eliminate the risk: some faults are not always visible and can cause costly incidents and breakdowns for your company. Indeed, most faults are the result of abnormal heating or cooling.

Only infrared thermography allows you to quickly observe a thermal scene and to highlight, without any contact, temperature differences on the surface of any type of object. Thus, by detecting these anomalies, often invisible to the naked eye, thermography allows corrective action to be taken before breakdowns or costly problems occur.

Here is a non-exhaustive list of benefits that will help you save energy:

* Inspection of systems during operation, without stopping production

* Identification and precise location of problems as soon as they appear

* Increase the useful life of equipment by monitoring its condition

* Simultaneous temperature measurement of multiple objects

* Accuracy of results and reliability of measurements

* Significant improvement in energy efficiency

* Reduces repair times by accurately locating faults

* Simple and fast measurement of large areas

You can inspect in temperature-controlled process areas, cold storage rooms, freezing tunnels and industrial clean rooms.

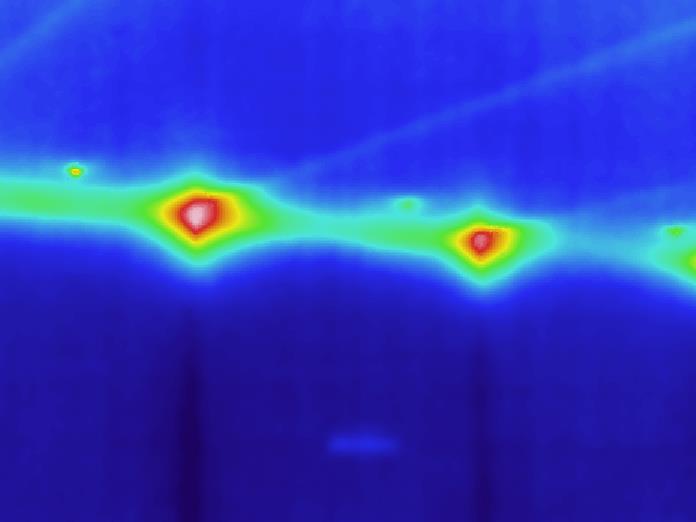

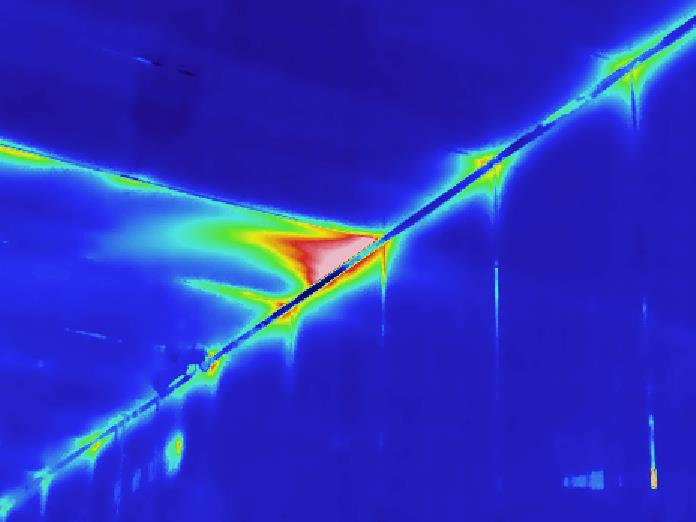

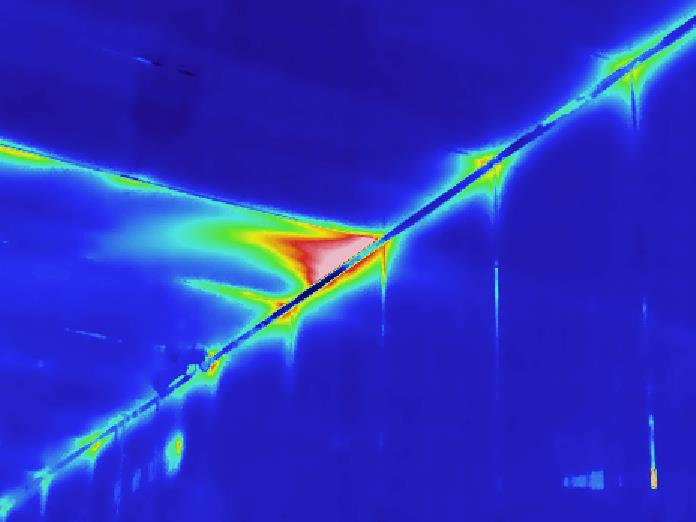

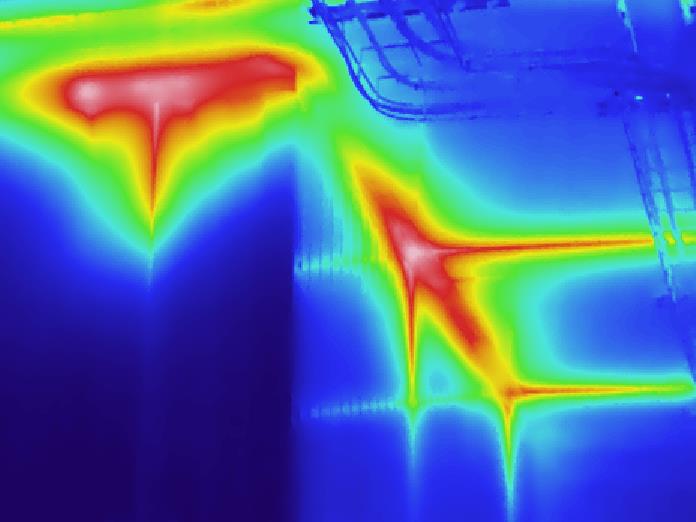

Thermographic inspection of cold storage rooms allows the detection of heat or cold loss, insulation problems in walls and ceilings. This inspection allows us to identify any thermal sealing defects in cold rooms and clean rooms in order to reduce energy losses and guarantee your environmental policy.

It is important to carry out an infrared thermography inspection of your cold room to detect and identify any leaks in the fluid networks, partitions and ceilings (junctions of isothermal panels, areas where technical elements are fixed, etc.).

This will reduce your energy losses and improve your environmental policy.

Exfiltration of cold air under the door (defective seal)

Irregularity of the insulation on the cold store roof

Carveen is a company with more than 40 years of experience in the rental/sale/breakdown/maintenance and installation of refrigeration and air conditioning equipment.

We have the equipment and the know-how of our certified and approved refrigeration technicians to carry out this type of inspection.

Thanks to Carveen, you will be able to save energy and be eco-responsible for your installations. Do not hesitate to contact us:

Share this content